Door hardware is increasingly needing to be automated with mechanical automation coming down to two fundamental methods: solenoid actuation and motorized actuation. Increasingly specific actuation is available with a choice of solenoid or motorized.

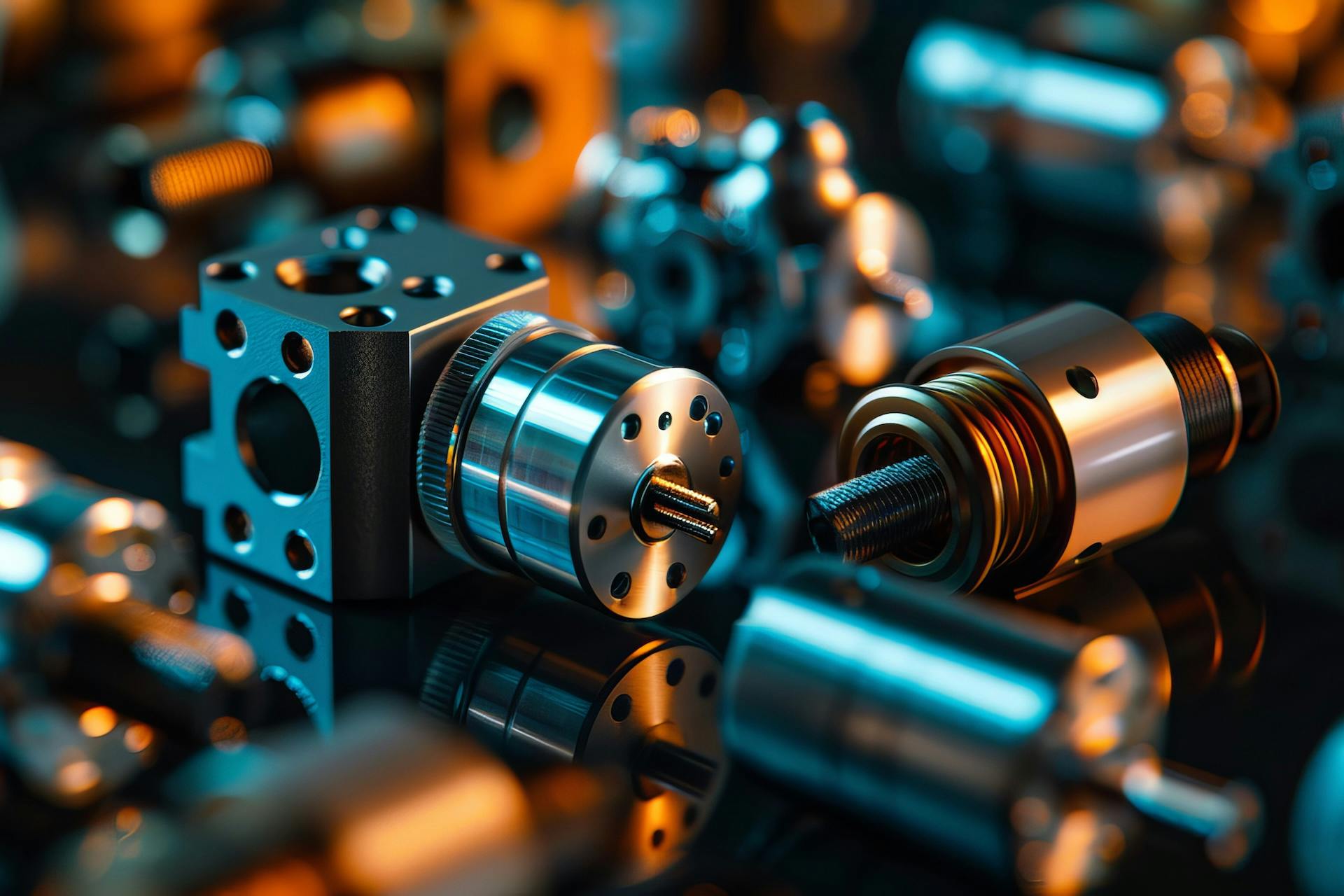

Both methods serve the same general purpose—automating the locking and unlocking of doors, releasing latches, or even opening and closing doors. While the end result is often the same, the technologies behind these solutions differ significantly. In this blog, we focus specifically on small solenoids and motors used in mortise and cylindrical locks, electric strikes, and exit trims, exploring their distinctions to help you make an informed decision based on specific needs.

Understanding Different Locking Mechanisms: Solenoid and Motorized Options

Motorized locks and solenoid locks operate using distinct mechanisms but achieve similar outcomes in certain applications. Both technologies are capable of moving the locking hub to secure or release the door. However, in applications involving latch retraction, motorized locks excel by directly retracting the latchbolt through the motor’s precise action. Solenoid locks, including solenoid strike plates, utilize electromagnetic action for engagement or disengagement, typically operating within the door frame as part of an electric strike assembly that replaces the standard strike plate.

Choosing the right locking mechanism involves aligning the lock with your specific requirements. Let’s break down the key considerations to help you make an informed decision.

Environment and Usage Demands

Motorized locks are particularly well-suited for continuous-duty applications, such as stairwell doors or other access points that remain engaged for extended periods. Their ability to efficiently handle constant operation while minimizing power consumption makes them an excellent choice for these scenarios. Additionally, they perform reliably in high-traffic environments like schools, hospitals, and office buildings, offering smooth, quiet operation without compromising durability.

Solenoid locks, especially those with smaller solenoids, are better suited for access points that require fast, reliable engagement but do not face the demands of continuous-duty operation. While they may not be as efficient in fail-safe applications requiring constant power, there is less that can go wrong over time due to a fewer number of components, making them reliable in many applications.

Power Efficiency and Lifecycle

Motorized locks stand out for their energy efficiency. They only draw power during operation, making them more efficient and reducing wear on the system. This efficiency not only contributes to a longer lifespan and lower maintenance costs but also reduces the workload and costs associated with power supplies. By minimizing the demand on power supplies, motorized locks can help extend their lifespan and reduce replacement frequency. The reduced power consumption also means lower long-term energy costs, making motorized locks a smart investment for facilities looking to minimize ongoing expenses.

Solenoid locks and solenoid strike plates both share similar power consumption patterns, especially in fail-safe configurations, Both tend to draw consistent power to maintain the locking state, which can lead to higher energy costs over time. While the upfront cost may be lower, these factors can contribute to higher total ownership costs in the long run.

Flexibility

Motorized locks offer significant adaptability, making them the ideal choice when the requirements of a door are uncertain or likely to change. Whether the application calls for fail-safe or fail-secure, motorized locks can be adjusted to suit the scenario. Operating on a wide voltage range of 11-30VDC, motorized locks provide additional flexibility, ensuring compatibility with various power supplies and systems. This versatility is especially valuable in environments where access control needs may evolve over time or when precise door requirements are not fully defined during installation.

In contrast, solenoid locks are more rigid in their configurations. Key features such as fail-safe or fail-secure operation and voltage requirements are typically set at the factory and cannot be modified in the field. This makes solenoid locks a good choice when the door's specific needs are well understood from the outset.

Ultimately, if you anticipate a need for future adaptability or are unsure about the specific door scenarios, motorized locks provide the flexibility to accommodate a range of applications.

Choosing the Right Lock for You

Both motorized and solenoid-based locking mechanisms have their strengths, but the best choice depends on your specific needs. Motorized locks offer superior performance, energy efficiency, and integration capabilities, making them ideal for modern access control applications.

For guidance in selecting the right locking mechanism for your application, reach out to our team of experts. We’re here to help you find a solution that balances security, functionality, and cost-efficiency.